ACU2-H Soft robot gripper control unit suit for demostration

ACU2-h / Active Control Unit

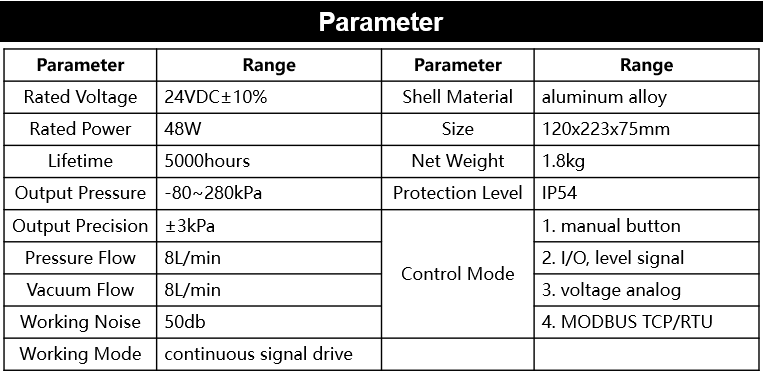

Compact active controller with flexible SOFT gripper. Small size, light weight, easy installation.

• Built-in air source, compact and light.

• -85~100kPa output pressure range, full support from soft beak to soft fingers and suction cup drive.

• Working positive pressure, working negative pressure can be adjusted by the panel button in real time.

• Integrated panel integrates digital display and operation buttons.

• With manual (button) and automatic (I/O level signal) two control modes, with a variety of mechanical arm, PLC

terminal.

• IP54 electrical protection grade, waterproof and dustproof, suitable for all kinds of bad working conditions, with

intelligent alarm function, safety, stability, no need to worry about disoperation.

1.Use the power adapter to power up the control unit.

2.Set working pressure according to the type of the gripper (IMPORTANT). Unlock the panel by referring to ‘F&Q’ and adjust the [Set Pressure] and [Set Vacuum] buttons to make the value in the digital display of [Set Work. Press.] equal to the using pressure of the gripper (consult our technical engineers).

3.Connect the [Gripper Port] to the gripper. If the pipe diameter is inconsistent, use the reducing joints in the fitting.

4.Operate the [Manual] button to check the working performance of the gripper. When the control unit is working, the pressure of the gripper can be observed in real time through the [Current Gripper Press.] digital display.

5.According to working conditions, select ports to connect with terminal equipment in the [Port Control].

F&Q

1.Unlock the panel adjustment button.

Two groups of adjustment buttons ([Set Pressure], [Set Vacuum]), [+] and [-] of any group are pressed for 3 seconds at the same time, until the value of the [Set Work. Press.] display meter on the panel flashes. If there is no operation within 10 seconds, the panel will be locked automatically.

2.The air pump starts intermittently every 2 seconds.

When the control unit is working, if the air pressure value of [Gripper Port] cannot reach the set air pressure value within 2 seconds, the air pump will restart automatically to prevent idling. In this case, please check whether the air path from the control unit [Gripper Port] to the gripper is leaking, causing the pressure cannot be reached.

3.The control unit working mode.

Under the condition that the air circuit of the gripper does not leak, after the air pressure inside the gripper is in place, it is in a pressure-holding state (the air pump stops working, and the gripper keeps the pressure state). If there is a change in the value of the [Set Gripper Press.] display meter or there is leakage in the air circuit, the control unit will start again until the air pressure is in place.

4.The state of the drive after a brief power loss.

There is a [Manual] signal before power off. After power on again, the manual signal will be cleared, the state of the gripper will continue to be maintained. And the air pressure value of the gripper will be displayed in the [Current Gripper Press.] display meter at the same time. Until the [Manual] signal is triggered again, the drive will work again.

There is a [Port Control] signal before power off, and it is a continuous signal. After power on again, the control unit will be corresponding state according to the real-time signal.

5.Priority of various control methods.

MODBUS TCP > MODBUS RTU > Analog Voltage > I/O > Manual